|

Purchase

|

||

|

Planning

|

|

Warehouse

|

Sales

|

Let’s start with some overview and then go to more details.

One of typical business cycles starts with purchasing some goods, then storing them in warehouse/shop, selling them to customers and planning next purchase.

Your exact process might be different, some steps might be merged or have different relations between each other and that’s Ok, every company is unique. Every step is just a building block for your company and how you connect them, that makes you unique.

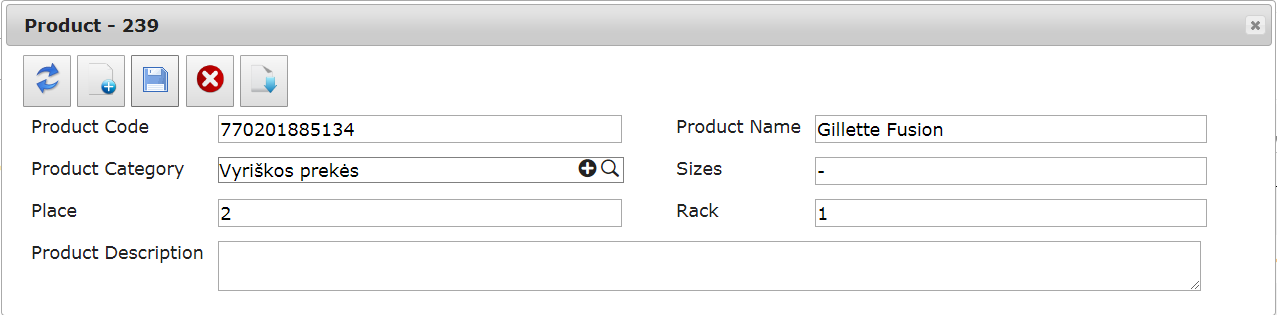

Products

We start with products – it’s what you buy and what you sell. And it doesn’t necessarily needs to be material product, it can be anything that you sell or buy. For example rent service is also a product.

Products also can be categorized – that helps when you need search something similar or you want to see some reports, plan or just have some overview.

Typical product window looks like this:

But it doesn’t need to be like this for you, if you have some specific data (for example validity date, color, etc), that you want to have in your product window, we will put them there. Every company is unique, therefore product definition can be different for each.

Though there are few fields, that are used by everyone – product code and name. Product code is usually assigned by manufacture and its purpose is to uniquely identify that product, while name is more readable text. Difference is, that there might be few products with same name, but their product codes will be different.

When you have our products, we can start buying them. This is done via purchase order.

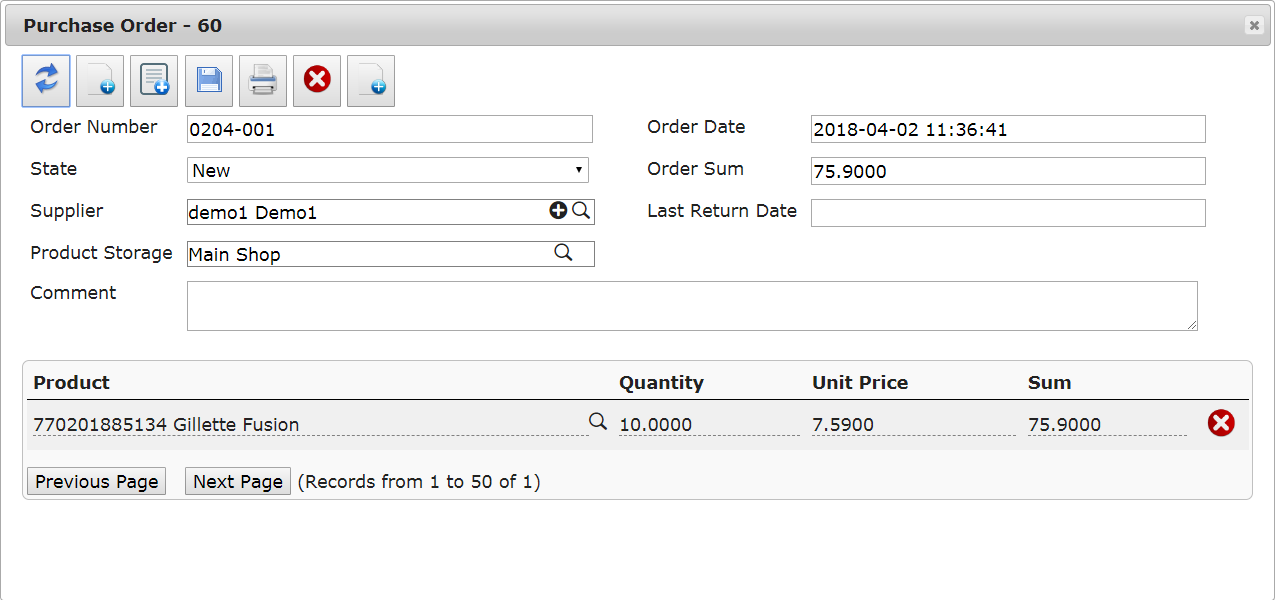

Purchase

Purchase order purpose is to record all your purchase operations. Most such typical orders will have order number – to identify this concrete order among others, supplier, order date and purchased products. In addition we also store, where will goods be stored. And any additional data you would like to have, just let us know, what would you like to have there.

After you bought your goods, they are delivered to our warehouse/store. And to avoid filling same data twice you can use order state to do that automatically.

How it works – when you create new purchase order, it will be initially in “New” state, after all information is put and you completed purchase, just set order state to “Finished” and rest will be done by program itself and you can see changes in warehouse immediately. You also can use intermediate state – “Confirmed”, which means that you have revised order, but it’s not yet received, but all the details in that order are correct.

|

New purchase

order |

Delivering goods

and changing order to finished. |

|

Of course all warehouse operations can be done manually, but we recommend to do it through orders, so you would spend less time and have more information. This especially helpful, when connected with planning rules.

But let’s go to next step – sales.

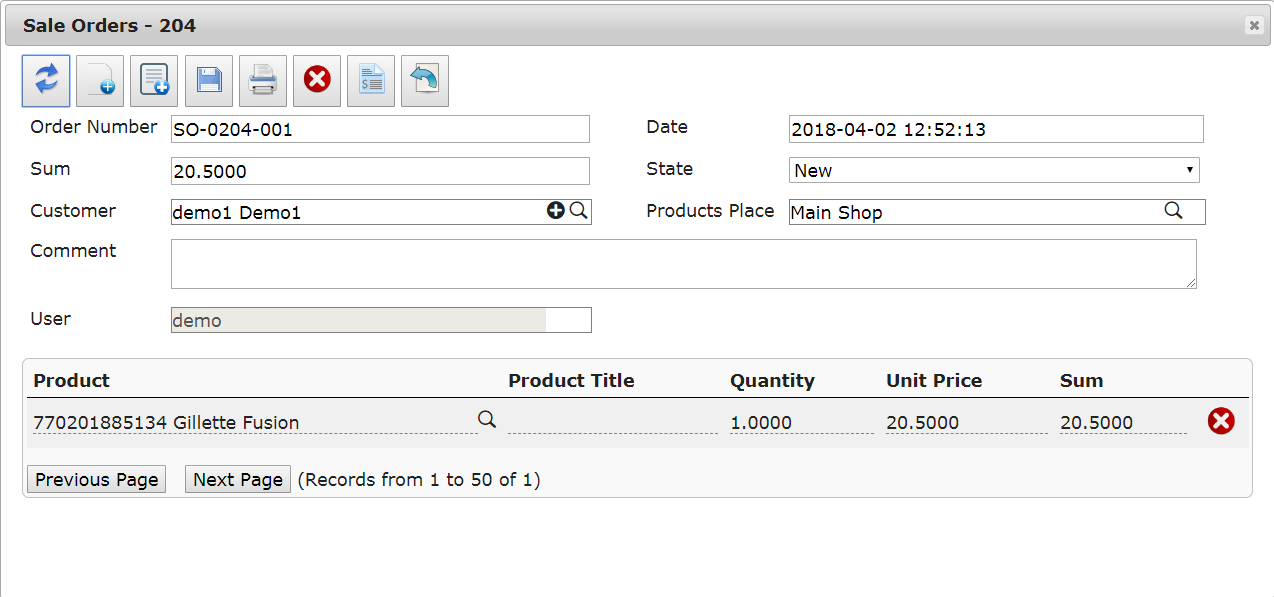

Sales

All sales operations are recorded with sale order.

It also contains order number – to uniquely identify sale order, date, customer – who bought your products, place – from where they were taken, sold items and some additional fields. And as in any other window, if you need to have some extra fields, just let us know and we will put them for you.

Same as with purchase order, sale order has state. When creating new sale order its state is set to “New”, when you give your items to customer it should be changed to “Finished” and reason is same as with purchase order – to automate warehouse operations.

And to make it easier, goods in sales also can be connected to price list.

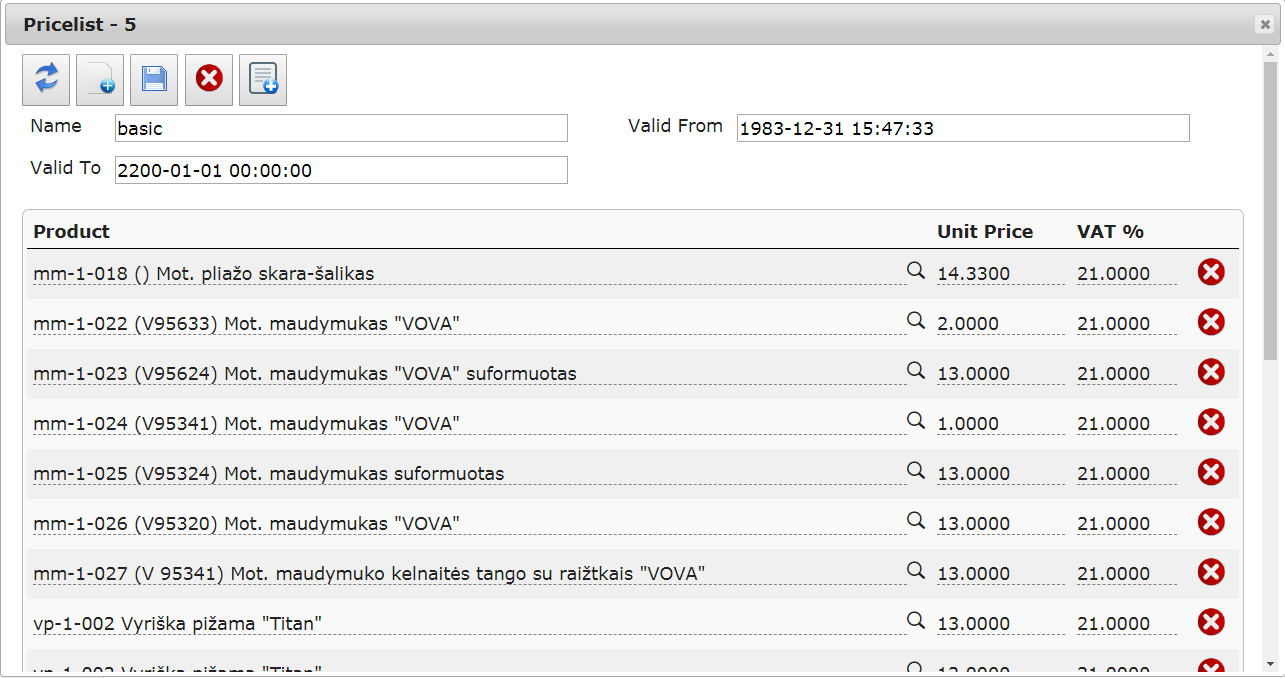

Price list

Every price list have name and dates – from when it is valid, to when it is valid. And products with prices. Most likely you will have just one price list, as it’s sufficient for most cases. But if you need you can have as many price lists as you like.

How it connects to sales? When you add new product to sale order it will check any valid price list for that product and if it finds any price information, that price will be put into sale order. So if you have same product sold over and over, you can put it into price list. You will save time and avoid unnecessary pricing errors. And will speed up your customer service.

Last big part of every company is to plan new purchases.

Planning

Planning is critical part of every business and it’s very important to have enough information to do it properly. For that we give reports, where you can see how much of some products was sold, or sales of some product category. If you have important customers, you can check, how much they bought and do any actions related to that. In addition, you can look for your purchase information as well, by products, categories or suppliers (maybe you can get bigger discount or search for new supplier). That’s usually enough information to start working on plans.

Another critical part is to execute these plans and here we can help a lot. When you decided, that you need to have so much of some product, you can create planning rule for that product and create your purchase order automatically.

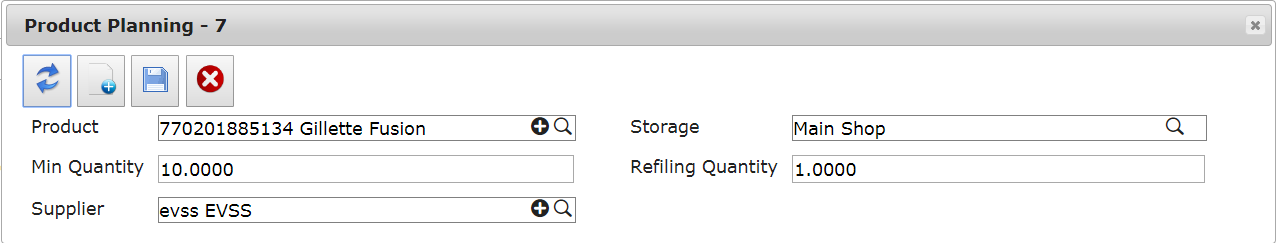

Planning rule contains product, that you are planning for. Storage is where this product is stored and what to monitor. Minimum quantity is product quantity that always should be in selected storage and refiling quantity is how much items needs to be bought, when product goes below minimum quantity. In addition you can select supplier, so when purchase order is created it will use this supplier.

Product planning is involved every time, when sale order is finished. It will check, that every product is above its limits and if some are below – will create purchase order for every missing product.

What you will need to do – is only check purchase order list, check that everything is Ok. If you put email into suppliers window, when you mark it as finished, email will be sent with order information directly to that supplier.